Using TPU on your F Series printer

Posted on 2019/01/15

SHARE

With the introduction of the new Stratasys Elastomer material TPU 92A, we have put together a short summary of what we feel you need to know about using TPU 92A on your printer.

TPU Filament Spools

- Always make sure to remove orange tape before loading

- When removing TPU spools from the system, always make sure you place the material spool in the Mylar bag immediately

- For extended non-use periods greater than 48 hours, unload the material from the head and wind back on the spool

- If the machine has been idle with TPU material loaded for more than 48 hours, unload the filament and cut off 6ft of the filament end and reload in to the printer

Part Accuracy

- Parts are produced within an accuracy of: +/- .254mm or +/- 0.003mm, whichever is greater

- Accuracy is geometry dependent

- Putting printed parts into a support removal tank may cause swelling of up to 0.5% which can result in the part being out of the accuracy tolerance initially

- Due to the nature of the TPU the visual quality of parts particularly fine feature details, may not be as high as it is for Rigid Materials such as ABS or ASA on the F123 platform

Part Quality

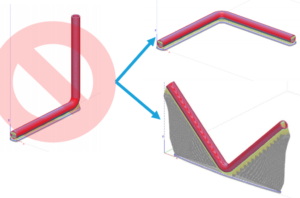

- If you experience any waves or ripple in parts as shown below, remember to check: tips are clear of any material debris, tips are adjusted to correct height or try reorienting parts for better results.

Part Orientation

- With the TPU 92A material, orientating for build success is the primary consideration. Then factors such as design intent and aesthetics can be considered

- Try to minimise the Z extent

- Watch for vertical areas that could be unstable

- Insight users can further stabilise by increasing the self supporting angle, switch to a different support style and/or use stabilise walls

Further questions? Drop us a line at: enquiries@3dprintacademy.co.uk

Book now or just need More Info?

Any questions or book one of our training courses please phone 03332 075660 or email enquiries@3dprintacademy.co.uk