Top tips for keeping your PolyJet system running smoothly

Posted on 2019/04/16

SHARE

1. Clean the print head after every job

It’s vital that you clean the print bed after every job to ensure that the surface is completely level for the next print. Failure to clean the bed each time can result in an uneven model, poor print quality and risk of catching the roller which can damage the printer.

Richard’s Tip – Make sure you only use water to do this as you don’t want to take the finish off the metal plate

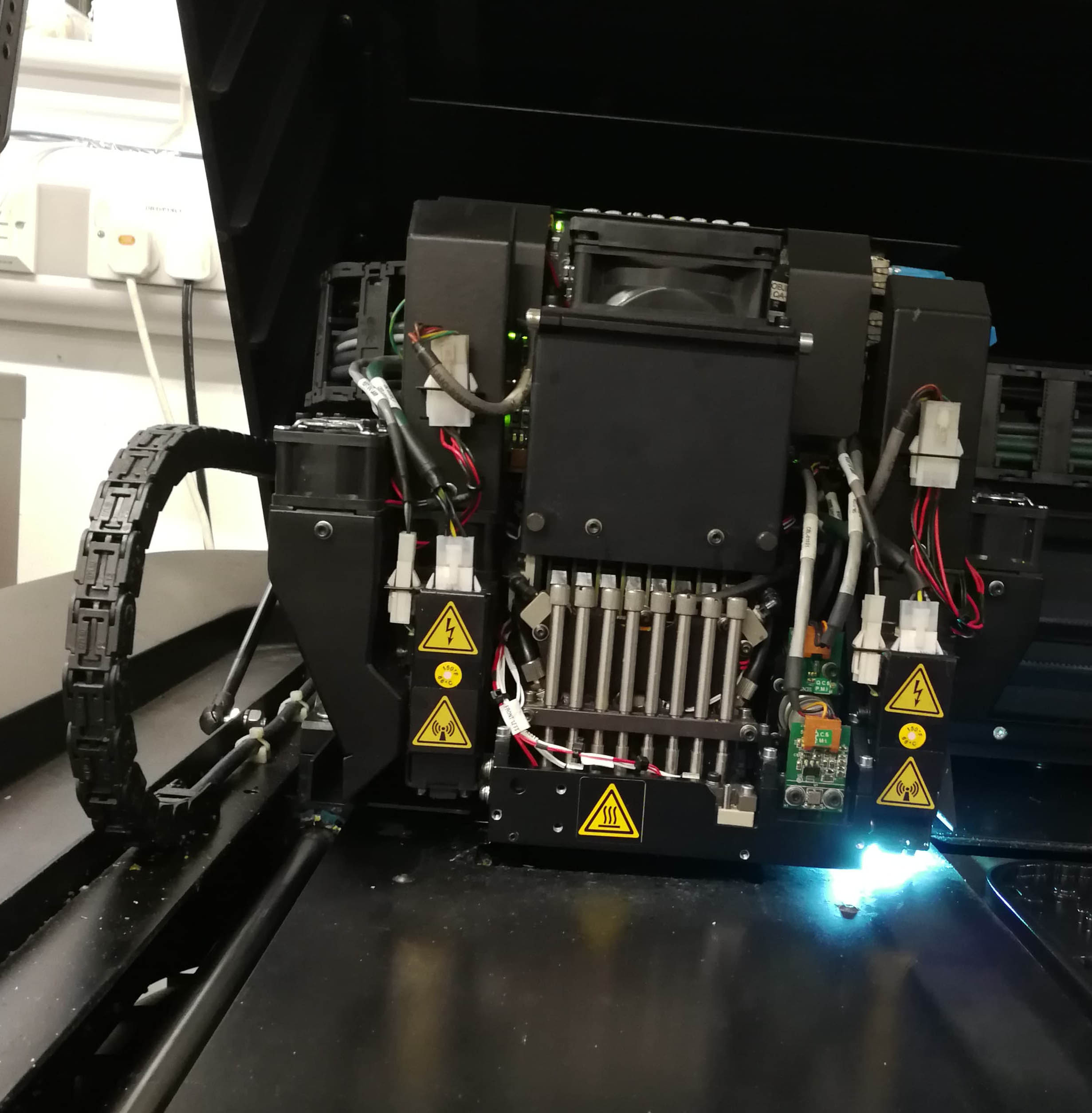

2. Cleaning the print heads

Cleaning the print heads is something which should also be done after every print. We know it can be a bit of a pain, however if the print heads are neglected it can cause a number of issues including clogged heads, nozzles misfiring and models with ridges in the surface finish.

It’s generally a straightforward task and can be carried out by basic operators using the wizard tool to get the print head into the correct position. From there you can use IPA and a lint free cloth to wipe the head from back to front.

Still experiencing issues?

If you haven’t used the printer in a while, you may need to perform a print head clean, even if it hasn’t been used. If you’re still experiencing issues at this stage, move on to our third tip…

3. Complete a pattern test and wiper assembly clean

The pattern test is used to check if all of the nozzles are firing correctly and should be carried out once a week. Whilst it’s not imperative that every single nozzle is working, if too many are faulty it can affect the quality of your print.

It you notice that more than a couple of nozzles are not working each week, you should attempt to clean the nozzles more frequently. If this does not help, it can be a sign that you need a new print head. The average life of your print head is roughly 2000-4000 hours, however this depends on how well you look after it.

As a last resort before investing in a new print head, you can try to remove the head and soak it in IPA. Please note that this step should only be carried out by an advanced user or an engineer as once the head is removed, you will need to recalibrate the machine again.

4. Check the print head alignment

It is crucial that you carry out this task every month as the PolyJet system is a precision piece of equipment and any slight movement of the printer can knock it out of alignment and affect your prints.

This process is again guided by the wizard tool and more information can be found in the print manual. However, for peace of mind that your team can competently carry out this procedure on a quick and easy basis, take a look at our level 1 PolyJet course.

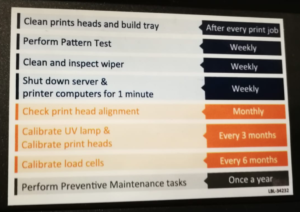

5. Stick to your maintenance schedule

To ensure the machine is operating to the best of its ability, make sure you stick to the maintenance schedule as advised by the manufacturer. You can find this guidance in the manual and on a sticker inside your machine.

By sticking to this schedule you will be ensuring maximum longevity of your machine, as well as avoiding costly replacements, engineer call outs, print errors and material wastage.

Our training team recommend putting a chart up on the wall above the printer to help your team keep track of what maintenance work has been carried out.

Finally, we asked our team if they had come across any maintenance disasters in their time….

Richard Bolam:

One of the most common mistakes we come across which can lead to a disaster if unnoticed is leaving a mirror inside the printer. When cleaning your print head, its standard procedure to use a small mirror to help you see inside the printer, however I’ve come across many customers who have forgotten to take the mirror out after! This means that when the printer is turned on, the mirror cracks and hundreds of tiny pieces of glass are shattered everywhere inside the printer. It’s a very costly mistake to make!

We understand that these five tasks can be monotonous to carry out so frequently and when you’re busy it’s easy to skip a week… or two. However, by sticking to the maintenance schedule, you will be facing less work in the long run. As our trainers like to say – treat your printer well and it will treat your business well in return!

Ensure you’re team are able to effectively carry out the PolyJet maintenance schedule with our PolyJet basic course.

For more advanced training which covers maintenance an engineer would carry out, please review our advanced user course.

Book now or just need More Info?

Any questions or book one of our training courses please phone 03332 075660 or email enquiries@3dprintacademy.co.uk