Part orientation for smooth surface finish in FDM

Posted on 2019/05/03

SHARE

For those who have used an FDM printer you will know that parts definitely don’t have the same surface finish as a Polyjet part for example. This is down to the technology printing the part and of course the materials. There are however ways that you can orient your part to give the smoothest FDM surface finish.

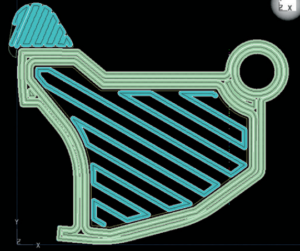

Better surface finishes will be achieved by building the surface in the xy plane. Any surface that is built in the z-axis will be stepped.

See below the process for achieving the best surface finish possible for your FDM part….

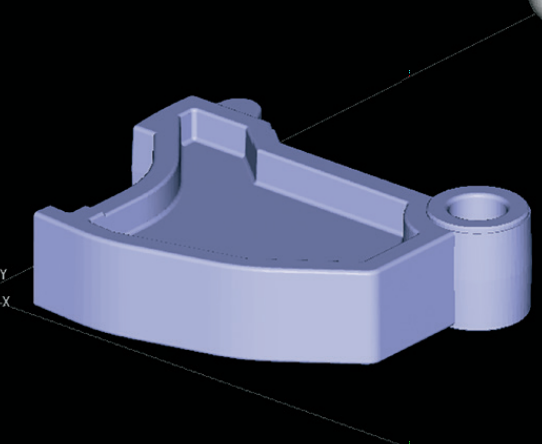

Step 1

Slice the part. Once sliced in this orientation, stepping is visible along the angled surfaces. This will produce a rough surface.

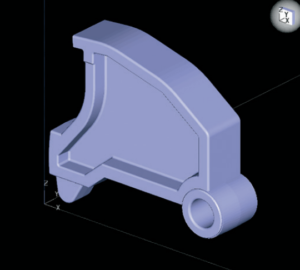

Step 2

Rotate the part around the x-axis. By rotating the part, surface finish will be greatly improved on the finished part.

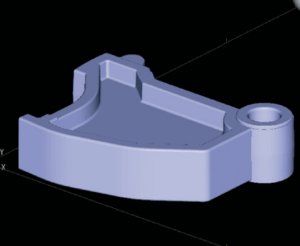

Step 3

Slice the file once again. If you notice the angled surface below is now being built in the xy plane. This will produce a smooth surface finish for your part.

Book now or just need More Info?

Any questions or book one of our training courses please phone 03332 075660 or email enquiries@3dprintacademy.co.uk