3D Printing in Nylon 12

Posted on 2019/03/19

SHARE

Nylon 12 is a popular FDM material that is used in traditional manufacturing processes. In the following article, our academy trainers will cover several different considerations to think about when you are printing in Nylon 12.

Tip Selection

With Nylon 12, the smaller the slice height the better the part aesthetics and surface finish. Larger slice heights can improve strength and toughness by up to 10% and build speed by 30% or more.

Available model tip sizes/slice heights:

- T20: 0.30mm/0.013in

- T16: 0.254mm/0.010in

- T12: 0.178mm/0.007in

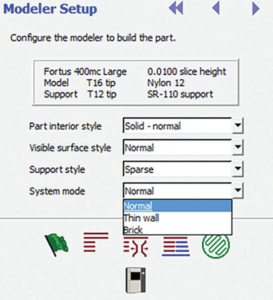

Build Modes

The build modes adjust the oven temperature to control the crystallisation rate and avoid melting or warping problems for various wall thicknesses.

Please note: users should select the build mode based on the thickest portion of the part geometry.

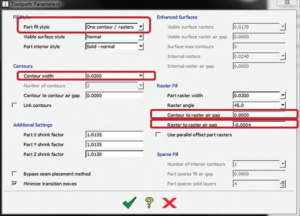

Porosity

There are three interior tool path variables to consider that can change the porosity of a part.

- Multiple contours: these can be used to hide raster turnarounds and enhance aesthetics

- Contour to raster air gap: you can decrease the contour to raster air gap to create a stronger part

- Raster to raster air gap: this default creates a slight overfill of the part and increases it’s strength

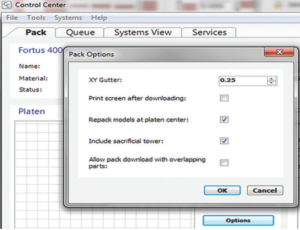

Sacrificial Tower Features

Nylon 12 is quite a sticky material. A sacrificial tower feature has been added to the Control Centre in the Insight Software to help increase part quality.

When packing a job in Control Centre, selection the options button & check the ‘Include sacrificial tower box’ in the pack options pop-up window.

Support Removal

Nylon 12 parts will be pliable at oven temperature. To maintain dimensional accuracy, either cool the oven to 75oC before removing the part, or remove it by handling the build sheet only.

Quick Tips

- Parts must be submerged in water for a minimum of 4 hours after building (this allows the part to maximise it’s mechanical properties and maintain it’s intended shape)

- All support material must be removed from the part otherwise it will make the part brittle

- Immerse parts in lower temperatures to reduce the risk of warping

For more information on printing with Nylon 12, or any of the other Stratasys thermoplastics – please get in touch with our team!

Book now or just need More Info?

Any questions or book one of our training courses please phone 03332 075660 or email enquiries@3dprintacademy.co.uk